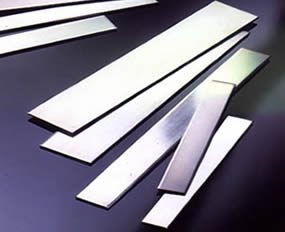

Our production of strips of the required width have no intermediate joins and feature excellent plastic deformability, which make possible to automate the knife handle moulding process, the result being considerable savings in terms of time and labour.

Cut-to-size bars are available for optimal coining of forks and spoons.

DATA SHEET – FLAT PRODUCTS FOR CUTLERY

The data sheet for this item is given below.

|

||||||||||||||||||

|

|

||||||||||||||||||||||||||||

The figures in bold are to be considered as binding upper and lower thresholds. The figures in plain character are not binding. They indicate the upper and lower thresholds in the range of reliability of the characteristics. |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

* = tolerance to ISO 3486 Requests for special alloys and size not envisaged in these tables will be the subject of specific agreements |

|

|

|