FOR BRIGHT PLATING BATHS USING CYANIDE, PYROPHOSPHATE AND ACID FLUROBORATE.

CuOF 2000 anodes are obtained using the oxygen-free process and are designed to meet the requirements of the electronics industry.

The CuOF 2000 anode is produced by melting a premium-quality grade A copper cathode.

Melting occurs in induction furnaces in an oxygen-free atmosphere.

The molten metal is then poured into the final mould in a protected atmosphere.

This process prevents the formation of harmful oxides and the inclusion of other impurities.

SEVEN REASONS WHY TO USE OXYGEN-FREE ALKALINE COPPER ANODES.

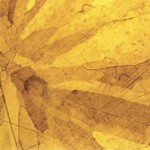

1. AN ELONGATED-GRAIN STRUCTURE HELPS PREVENT ROUGHNESS AND GIVES AN EVEN COATING.

Like in other metals, most of copper oxides form in peripheral grains. These impurities are subject to etching from electrolytic bath solutions. The tiny particles or other impurities present in peripheral grains may create roughness on the deposit. The purity and structure of CuOF 2000 anodes ensures a more consistent and smoother surface finish.

2. NO ADDITIVES MEANS SMOOTHER COATING.

As the absence of oxygen is obtained without the addition of additives, there are no traces of contaminants in CUOF 2000 anodes, which reduces the amount of insoluble particles in the bath.

3. LESS SLUDGE MEANS LESS PLATING VAT MAINTENANCE.

The purity of the CuOF 2000 anode helps reduce the amount of sludge in the plating baths. The absence of copper oxide particles and the low level of other impurities means less sludge and film that form on the anode in cyanide plating baths. The amount of film can be controlled by modifying the electric current density on the anode. CuOF 2000 copper anodes can withstand a higher current density than other conventional anodes.

4. NO BAGS MEANS LESS DEAD TIMES.

In most cases, the use of CuOF 2000 anodes free of impurities eliminates the need for using bags. This prevents the accumulation of metal in the bag thus reducing cleaning, all the metal is used for the process, without waste. The use of bags tends to slow deposition with the consequent need to increase the number of anodes in the baths. Moreover, the bag tends to increase the amount of ionized copper in the solution, thus creating an increase in the polarisation of the anode and a reduction of its efficiency. Without bags, the CuOF 2000 anodes create greater current density, thus

allowing deposition at a faster rate, which results in cost saving.

5. EVEN DISSOLUTION MEANS LESS ANODES TO DISCARD.

CuOf 2000 copper anodes dissolve more evenly than any other anode. In cyanide, fluoborate and pyrophosphate plating baths, the anode dissolves completely, which minimizes the amount of anode to be scrapped.

6. GUARANTEED DEPOSITION THICKNESS MEANS NO WASTE.

Even a relatively thin deposition, if made using a CuOF 2000 anode, gives a smooth, even and consistent coating. Achieving the same result using electrolytic copper anodes would require a thicker deposition.

7. AN ANODE DESIGNED FOR BRIGHT PLATING BATHS USING CYANIDE,PYROPHOSPHATE AND FLUOBORATE ACID SOLUTIONS.

The use of the CUOF 2000 anode with these three solutions results in reduced maintenance.

DATA SHEET: PACKAGING FOR OXYGEN-FREE ALKALINE COPPER ANODES.

|

||||||||||||||||

|

DATA SHEET – CuOF 2000

The following specifications may vary according to the type of installation, technologies used and the amount of impurities in the raw materials.

|

||||||||||||||||||||||||||||||||||||||||||

|

Micrografia dell’anodo CuOF 2000 evidenziante la struttura larga e densa del grano, privo di inclusioni.